- Home Page

- Company Profile

-

Our Products

- Packaging Machines

- Pepsi Sealing Cutting Machine

- Turn Table

- Front Back Labeling Machine

- Litchi Juice Filliing And Sealing Machine

- Mixing Tank

- Tray Dryer

- Rotary Bottle Washing Machine

- Automatic Sticker Labeling Machine

- Bottle Sealing Machine

- Tin Can Seamer Ropp Cap

- Double Chamber Vacuum Packing Machine.

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Homogenizer Machine

- Planetary Mixer

- Hand Tube Crimping Machine

- Heat Sealing Machines

- Capsule Filling Machine

- Ribbon blender

- Processing tank

- Capping Machine

- Crown Capping Machine

- Semi Foot Operated Ropp Capping Machine

- Automatic Cap Sealing Machine

- Bottle Capping Machine

- Automatic Sanitizer Bottle Filling Capping Machines

- Automatic Ropp Cap Sealing Machine / Screw Capping Machine

- Rotary Bottle Capping Machine

- Ropp Cap Sealing Machine

- Aluminium Lug Capping Machine

- Lug Capping Machine

- Hot Ghee Filling And Capping Machine

- Automatic Sanitiser Bottle Capping Machine

- Automatic saline bottle filling inner cap outer cap crimping machine

- Lug Capping Machines

- Crona Test Tube Filling Capping Machine

- Automatic Bottle Filling Capping Machine

- Volumetric Filling And Ropp Capping Machine

- Semi Lug Capping Machine

- Rotary Ropp Screw Cap Sealing Machine

- Pouch Packing Machine

- Pouch Packaging Machine

- Pouch Filling and Packing Machine

- Flow Wrap Machine

- 2 head standy pouch packing machine

- oil pouch packing machine

- Powder Pouch Filling and Sealing Machines

- Liquid Pouch Filling and Sealing Machines

- Automatic Pouch Packing Machine

- Weight Metric Pouch Packing Machine

- Gel Pouch Packing Machine

- Automatic Grease Pouch Packaging Machine

- Milk Pouch Packing Machine

- stand up pouch packing machine

- Automatic Grease Pouch Filling Machine

- Safety Pin Packaging Machine

- Cartridge Pouch Packing Machine

- Powder Filling Machine

- Water Pouch Packing Machine

- Juice Filling Sealing Machine

- Tube Filling Sealing Machine

- Liquid Juice Filling Machine

- Hot Juice Filling Machine

- Oil Filling Machine

- Curd Filling Sealing Machine

- Tube Filling Machine

- Multi Head Filling Machine

- Auger Filler Machines

- Weight Metric Filling Machines

- Candy Pouch Packing Machine

- Foil Sealing Machine

- Pouch Packing Machines

- Flow Wrap Machines

- Cup Filling Machines

- Sealing Machines

- Shrink Tunnel And L Sealer

- Conveyors

- Washing Machine

- Labeling Machine

- Volumetric Filling Machine

- 6 Head Volumetric Filling Machine

- Rinsing Filling Capping Machine

- Filling Capping Machine

- Fully Pneumatic 2 Head Filling Machine

- Automatic Filling Machine

- Edible Oil Filling Machines

- Automatic Filling Capping Machine

- Liquid Packing Machine

- Shampoo Filling Machine

- Glucose Filling Machine

- Gravity Filling Machine

- Packaging Machines

- Contact Us

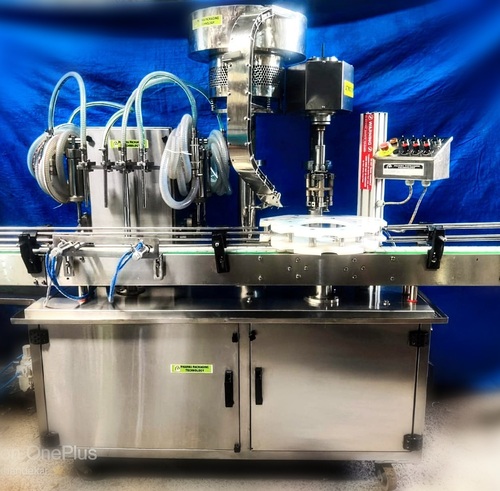

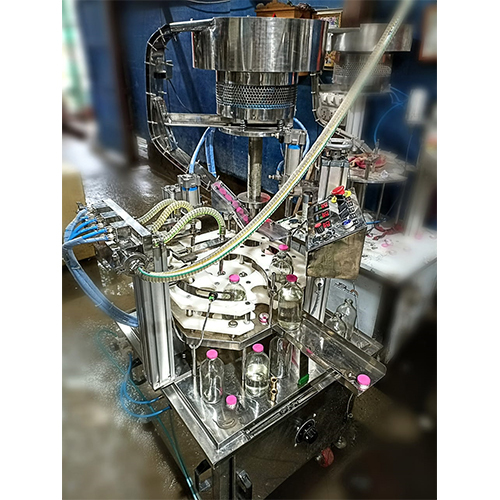

Volumetric Filling And Ropp Capping Machine

300000 INR/Number

Product Details:

- Application Pharmaceutical, Food & Beverage, Cosmetic, Chemical Industries

- Features No bottle no fill system, Synchronized filling & capping, Drip proof nozzle

- Noise Level Low

- Usage Liquid bottle filling and capping

- Filling Range 50 ml 1000 ml (adjustable)

- Power Supply Electric

- Type Volumetric Filling and Ropp Capping Machine

- Click to View more

X

Volumetric Filling And Ropp Capping Machine Price And Quantity

- 300000.00 - 400000.00 INR/Number

- 300000 INR/Number

- 1 Number

Volumetric Filling And Ropp Capping Machine Product Specifications

- Capping Machine

- Yes

- 1800 mm x 950 mm x 1900 mm

- 220V/380V, 50/60 Hz

- PLC Control Panel

- Pharmaceutical, Food & Beverage, Cosmetic, Chemical Industries

- 50 ml 1000 ml (adjustable)

- ROPP Sealing

- Stainless Steel

- Electric

- Approx. 450 kg

- 30-120 bottles per minute (varies by model)

- Liquid bottle filling and capping

- Silver

- No bottle no fill system, Synchronized filling & capping, Drip proof nozzle

- Low

- 2.5 kW

- Electric

- High Filling Accuracy, Easy Operation, Low Maintenance

- Volumetric Filling and Ropp Capping Machine

- Automatic

Volumetric Filling And Ropp Capping Machine Trade Information

- 1 Number Per Week

- Week

- All India

Product Description

Experience matchless efficiency and savings with our Volumetric Filling And Ropp Capping Machine, engineered for the finest bottle packaging standards. Featuring customizable filling heads (4/6/8), quick-release change parts, and a user-friendly touch screen interface, this automatic PLC-controlled system suits diverse bottle sizes for pharmaceutical, food & beverage, cosmetic, and chemical applications. Built with robust SS316 and SS304 stainless steel, it ensures high filling accuracy, low maintenance, and dependable safety. Favorable reviews highlight its gorgeous design, special rate offers, and advanced features including CIP compatibility, no bottle-no fill system, and overload protection. Exported across India and globally.

Outstanding Features & Versatile Applications

This machine boasts high filling accuracy, a synchronized filling and capping process, drip-proof nozzles, and low noise operation. With quick-release parts for various bottle sizes, it's primarily used in liquid bottle filling and ROPP capping across pharmaceuticals, food & beverage, cosmetics, and chemicals. As India's trusted exporter, manufacturer, and service provider, it sets industry standards for reliability and performance.

Main Export Markets & Supply Terms

We ship to major domestic and international markets, offering flexible payment terms and dependable transport services. The machine's supply ability ensures on-time shipments to various regions, catering to industrial clients. Designed for both domestic and overseas customers, our export network guarantees efficient logistics and secure delivery supported by responsive customer service.

Outstanding Features & Versatile Applications

This machine boasts high filling accuracy, a synchronized filling and capping process, drip-proof nozzles, and low noise operation. With quick-release parts for various bottle sizes, it's primarily used in liquid bottle filling and ROPP capping across pharmaceuticals, food & beverage, cosmetics, and chemicals. As India's trusted exporter, manufacturer, and service provider, it sets industry standards for reliability and performance.

Main Export Markets & Supply Terms

We ship to major domestic and international markets, offering flexible payment terms and dependable transport services. The machine's supply ability ensures on-time shipments to various regions, catering to industrial clients. Designed for both domestic and overseas customers, our export network guarantees efficient logistics and secure delivery supported by responsive customer service.

FAQ's of Volumetric Filling And Ropp Capping Machine:

Q: How does the Volumetric Filling And Ropp Capping Machine ensure high filling accuracy?

A: The machine utilizes advanced volumetric filling technology and synchronized filling and capping systems, ensuring each bottle is filled to precise levels. Drip-proof nozzles and PLC control further support consistent results.Q: What bottle sizes are compatible with the machine?

A: It accommodates bottle diameters from 30 mm to 100 mm and heights from 75 mm to 300 mm, with quick-release change parts allowing easy adjustments for different bottle sizes.Q: Where can this machine be effectively used?

A: The machine is ideal for pharmaceutical, food & beverage, cosmetic, and chemical industries, supporting liquid filling and ROPP capping applications in both small and large-scale production environments.Q: What is the process for cleaning and maintaining the machine?

A: It is compatible with CIP (Clean-In-Place) systems for efficient cleaning, while the centralized lubrication system and overload protection ensure low-maintenance and prolonged machine life.Q: What are the key benefits of the touch screen interface?

A: The touch screen interface provides easy operation, quick troubleshooting, real-time monitoring, and facilitates fast setup changes for different models or bottle sizes.Q: How do you handle shipment and delivery for domestic and export orders?

A: We utilize reliable transport services for prompt and secure shipment to both domestic and export markets, backed by strong logistics and customer support.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Capping Machine ' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free