- Home Page

- Company Profile

-

Our Products

- Packaging Machines

- Pepsi Sealing Cutting Machine

- Turn Table

- Front Back Labeling Machine

- Litchi Juice Filliing And Sealing Machine

- Mixing Tank

- Tray Dryer

- Rotary Bottle Washing Machine

- Automatic Sticker Labeling Machine

- Bottle Sealing Machine

- Tin Can Seamer Ropp Cap

- Double Chamber Vacuum Packing Machine.

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Homogenizer Machine

- Planetary Mixer

- Hand Tube Crimping Machine

- Heat Sealing Machines

- Capsule Filling Machine

- Ribbon blender

- Processing tank

- Capping Machine

- Crown Capping Machine

- Semi Foot Operated Ropp Capping Machine

- Automatic Cap Sealing Machine

- Bottle Capping Machine

- Automatic Sanitizer Bottle Filling Capping Machines

- Automatic Ropp Cap Sealing Machine / Screw Capping Machine

- Rotary Bottle Capping Machine

- Ropp Cap Sealing Machine

- Aluminium Lug Capping Machine

- Lug Capping Machine

- Hot Ghee Filling And Capping Machine

- Automatic Sanitiser Bottle Capping Machine

- Automatic saline bottle filling inner cap outer cap crimping machine

- Lug Capping Machines

- Crona Test Tube Filling Capping Machine

- Automatic Bottle Filling Capping Machine

- Volumetric Filling And Ropp Capping Machine

- Semi Lug Capping Machine

- Rotary Ropp Screw Cap Sealing Machine

- Pouch Packing Machine

- Pouch Packaging Machine

- Pouch Filling and Packing Machine

- Flow Wrap Machine

- 2 head standy pouch packing machine

- oil pouch packing machine

- Powder Pouch Filling and Sealing Machines

- Liquid Pouch Filling and Sealing Machines

- Automatic Pouch Packing Machine

- Weight Metric Pouch Packing Machine

- Gel Pouch Packing Machine

- Automatic Grease Pouch Packaging Machine

- Milk Pouch Packing Machine

- stand up pouch packing machine

- Automatic Grease Pouch Filling Machine

- Safety Pin Packaging Machine

- Cartridge Pouch Packing Machine

- Powder Filling Machine

- Water Pouch Packing Machine

- Juice Filling Sealing Machine

- Tube Filling Sealing Machine

- Liquid Juice Filling Machine

- Hot Juice Filling Machine

- Oil Filling Machine

- Curd Filling Sealing Machine

- Tube Filling Machine

- Multi Head Filling Machine

- Auger Filler Machines

- Weight Metric Filling Machines

- Candy Pouch Packing Machine

- Foil Sealing Machine

- Pouch Packing Machines

- Flow Wrap Machines

- Cup Filling Machines

- Sealing Machines

- Shrink Tunnel And L Sealer

- Conveyors

- Washing Machine

- Labeling Machine

- Volumetric Filling Machine

- 6 Head Volumetric Filling Machine

- Rinsing Filling Capping Machine

- Filling Capping Machine

- Fully Pneumatic 2 Head Filling Machine

- Automatic Filling Machine

- Edible Oil Filling Machines

- Automatic Filling Capping Machine

- Liquid Packing Machine

- Shampoo Filling Machine

- Glucose Filling Machine

- Gravity Filling Machine

- Packaging Machines

- Contact Us

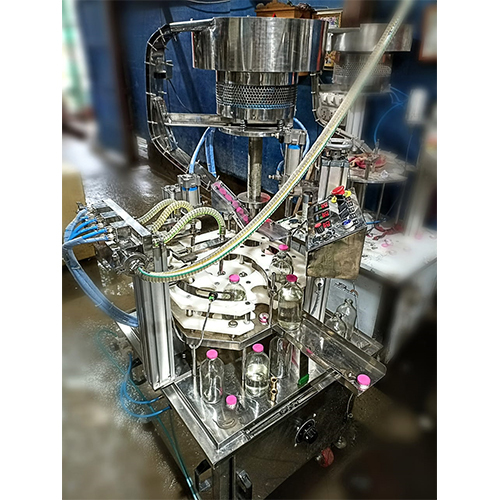

Automatic saline bottle filling inner cap outer cap crimping machine

Product Details:

- Usage Saline/IV bottle filling and sealing

- Power Supply Single/Three Phase AC

- Filling Range 50 ml to 1000 ml

- Noise Level Less than 70 dB

- Features No Bottle No Fill System, Drip-Free Filling, Easy Maintenance, Adjustable Speed

- Application Pharmaceutical, Hospital, Laboratory saline bottle packaging

- Type Automatic Saline Bottle Filling Inner Cap Outer Cap Crimping Machine

- Click to View more

X

Automatic saline bottle filling inner cap outer cap crimping machine Product Specifications

- Stainless Steel (SS304/316)

- Saline/IV bottle filling and sealing

- 2.5 kW

- Electric

- Yes

- Filling and Sealing Machine

- No Bottle No Fill System, Drip-Free Filling, Easy Maintenance, Adjustable Speed

- 50 ml to 1000 ml

- Approx. 650 kg

- 220-240 V, 50/60 Hz

- Less than 70 dB

- Automatic Saline Bottle Filling Inner Cap Outer Cap Crimping Machine

- PLC Control with Touchscreen HMI

- Fully Automatic

- Aluminum Crimp/Plastic Cap Sealing

- Up to 60 bottles/min (varies with bottle volume)

- Pharmaceutical, Hospital, Laboratory saline bottle packaging

- Single/Three Phase AC

- Precise Filling, Integrated Cap Placement, Accurate Crimping

- 2200 mm x 1200 mm x 1800 mm

- Metallic Silver

Automatic saline bottle filling inner cap outer cap crimping machine Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Per Month

- 3 Week

- Yes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Experience a prodigious leap in packaging efficiency with our Automatic Saline Bottle Filling, Inner Cap, Outer Cap Crimping Machine. Crafted in impeccable metallic silver with robust stainless steel construction (SS304/316), this rarefied solution is designed for both Glass and HDPE bottles, ensuring filling accuracy within 1%. The machine boasts integrated crimping heads-pneumatic or mechanical-and a fully automated cap feeding via elevator. Fresh orders are handled swiftly, with up to 60 bottles per minute. Ideal for pharmaceutical, hospital, and laboratory saline bottle packaging, now available for sale from India's premier exporter, manufacturer, supplier, and service provider.

Distinctive Features and Application Advantages

The machine incorporates exceptional features including Drip-Free Filling, No Bottle No Fill System, and Centralized Lubrication for easy maintenance. Its advanced CIP cleaning system and adjustable speed deliver seamless operation. Suitable for pharmaceutical, medical, and laboratory saline/IV bottle filling, it offers advantages like precise dosing, integrated cap placement, and reliable aluminum/plastic cap sealing. Application media ranges from saline solutions to other injectable fluids, ensuring consistent quality in every batch.

Market Reach, Delivery and Logistics

Targeted at India's vast domestic pharmaceutical and healthcare market, our machine is primed for swift logistics and quick dispatch, minimizing downtime for end users. Main export markets include Southeast Asia, the Middle East, and Africa, with robust freight arrangements to ensure timely delivery. Orders are processed efficiently, supporting seamless domestic and international distribution under reliable logistics networks for both large-scale hospitals and laboratories.

Distinctive Features and Application Advantages

The machine incorporates exceptional features including Drip-Free Filling, No Bottle No Fill System, and Centralized Lubrication for easy maintenance. Its advanced CIP cleaning system and adjustable speed deliver seamless operation. Suitable for pharmaceutical, medical, and laboratory saline/IV bottle filling, it offers advantages like precise dosing, integrated cap placement, and reliable aluminum/plastic cap sealing. Application media ranges from saline solutions to other injectable fluids, ensuring consistent quality in every batch.

Market Reach, Delivery and Logistics

Targeted at India's vast domestic pharmaceutical and healthcare market, our machine is primed for swift logistics and quick dispatch, minimizing downtime for end users. Main export markets include Southeast Asia, the Middle East, and Africa, with robust freight arrangements to ensure timely delivery. Orders are processed efficiently, supporting seamless domestic and international distribution under reliable logistics networks for both large-scale hospitals and laboratories.

FAQ's of Automatic saline bottle filling inner cap outer cap crimping machine:

Q: How does the automatic saline bottle filling and crimping machine ensure precise filling accuracy?

A: The machine employs a sophisticated PLC control system with touchscreen HMI, allowing for accurate volume setting and real-time monitoring. Its filling accuracy consistently delivers within 1% of the desired volume, accommodating bottle sizes ranging from 50 ml to 1000 ml.Q: What cleaning process is integrated for this machine to maintain hygiene standards?

A: It features an advanced CIP (Clean-In-Place) system, enabling automated internal cleaning without dismantling parts, which is crucial for maintaining strict hygiene in pharmaceutical and hospital environments.Q: When is this machine most beneficial for users?

A: This equipment is especially advantageous during high-volume production cycles, ensuring quick changeover times under 15 minutes, and when precise, drip-free filling and secure cap placement are required for saline or IV solution packaging.Q: Where can the automatic saline bottle filling crimping machine be effectively utilized?

A: It is ideally suited for pharmaceutical manufacturing units, hospitals, laboratory settings, and any facility involved in the packaging of saline or intravenous solutions, ensuring safe, contamination-free filling and sealing.Q: What are the steps involved in the bottle filling and crimping process?

A: First, bottles are automatically fed into the system, followed by accurate dosing of saline solution. The integrated cap elevator feeds inner and outer caps before the pneumatic or mechanical crimping head secures each with adjustable force, and capped bottles exit ready for distribution.Q: How does usage of this machine benefit operational efficiency?

A: The fully automatic design reduces manual intervention, accelerates production speed up to 60 bottles per minute, and minimizes the risk of errors. Its computerized controls facilitate easy maintenance, boost productivity, and ensure consistency across batches.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Capping Machine ' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free