- Home Page

- Company Profile

-

Our Products

- Packaging Machines

- Pepsi Sealing Cutting Machine

- Turn Table

- Front Back Labeling Machine

- Litchi Juice Filliing And Sealing Machine

- Mixing Tank

- Tray Dryer

- Rotary Bottle Washing Machine

- Automatic Sticker Labeling Machine

- Bottle Sealing Machine

- Tin Can Seamer Ropp Cap

- Double Chamber Vacuum Packing Machine.

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Homogenizer Machine

- Planetary Mixer

- Hand Tube Crimping Machine

- Heat Sealing Machines

- Capsule Filling Machine

- Ribbon blender

- Processing tank

- Capping Machine

- Crown Capping Machine

- Semi Foot Operated Ropp Capping Machine

- Automatic Cap Sealing Machine

- Bottle Capping Machine

- Automatic Sanitizer Bottle Filling Capping Machines

- Automatic Ropp Cap Sealing Machine / Screw Capping Machine

- Rotary Bottle Capping Machine

- Ropp Cap Sealing Machine

- Aluminium Lug Capping Machine

- Lug Capping Machine

- Hot Ghee Filling And Capping Machine

- Automatic Sanitiser Bottle Capping Machine

- Automatic saline bottle filling inner cap outer cap crimping machine

- Lug Capping Machines

- Crona Test Tube Filling Capping Machine

- Automatic Bottle Filling Capping Machine

- Volumetric Filling And Ropp Capping Machine

- Semi Lug Capping Machine

- Rotary Ropp Screw Cap Sealing Machine

- Pouch Packing Machine

- Pouch Packaging Machine

- Pouch Filling and Packing Machine

- Flow Wrap Machine

- 2 head standy pouch packing machine

- oil pouch packing machine

- Powder Pouch Filling and Sealing Machines

- Liquid Pouch Filling and Sealing Machines

- Automatic Pouch Packing Machine

- Weight Metric Pouch Packing Machine

- Gel Pouch Packing Machine

- Automatic Grease Pouch Packaging Machine

- Milk Pouch Packing Machine

- stand up pouch packing machine

- Automatic Grease Pouch Filling Machine

- Safety Pin Packaging Machine

- Cartridge Pouch Packing Machine

- Powder Filling Machine

- Water Pouch Packing Machine

- Juice Filling Sealing Machine

- Tube Filling Sealing Machine

- Liquid Juice Filling Machine

- Hot Juice Filling Machine

- Oil Filling Machine

- Curd Filling Sealing Machine

- Tube Filling Machine

- Multi Head Filling Machine

- Auger Filler Machines

- Weight Metric Filling Machines

- Candy Pouch Packing Machine

- Foil Sealing Machine

- Pouch Packing Machines

- Flow Wrap Machines

- Cup Filling Machines

- Sealing Machines

- Shrink Tunnel And L Sealer

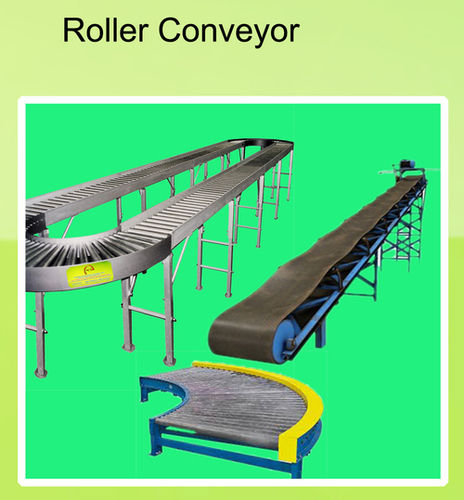

- Conveyors

- Washing Machine

- Labeling Machine

- Volumetric Filling Machine

- 6 Head Volumetric Filling Machine

- Rinsing Filling Capping Machine

- Filling Capping Machine

- Fully Pneumatic 2 Head Filling Machine

- Automatic Filling Machine

- Edible Oil Filling Machines

- Automatic Filling Capping Machine

- Liquid Packing Machine

- Shampoo Filling Machine

- Glucose Filling Machine

- Gravity Filling Machine

- Packaging Machines

- Contact Us

Automatic Dry Fruit Fill Sealing Machine

200000 INR/Number

Product Details:

- Belt Type Flat food-grade conveyor belt

- Features PLC control, touch panel operation, minimal waste, high accuracy

- Power Source Electric

- Thickness Body thickness 2 mm

- Surface Finish Mirror/Matte finish

- Material SS304 stainless steel

- Type Automatic fill and seal

- Click to View more

X

Automatic Dry Fruit Fill Sealing Machine Price And Quantity

- 1 Number

- 200000 INR/Number

- 200000.00 - 400000.00 INR/Number

Automatic Dry Fruit Fill Sealing Machine Product Specifications

- 2.5 kW

- Corrosion and wear resistant

- Up to 1 Kg per pack

- Automatic fill and seal

- Dry fruit packing, confectionery, nuts, seeds, snacks

- Included, food grade material

- Mirror/Matte finish

- Electric

- Body thickness 2 mm

- Stainless steel frame

- Integrated for precise transfer

- Flat food-grade conveyor belt

- Available

- 30-60 packs/minute (depends on product and pack size)

- PLC control, touch panel operation, minimal waste, high accuracy

- 220 V, Single Phase, 50 Hz

- Optional

- SS304 stainless steel

Automatic Dry Fruit Fill Sealing Machine Trade Information

- 1 Number Per Week

- 3-4 Week

Product Description

Discover the Automatic Dry Fruit Fill Sealing Machine-a famed best-seller noted for its optimum performance and ravishing build quality. Backed by favorable reviews and promising instant savings, this machine boasts a stainless steel frame, corrosion resistance, and seamless continuous operation. Featuring advanced Siemens PLC and HMI control, precise weigh filling, and heat sealing with temperature control, it supports PP, laminate, PE, and various food-grade films. Engineered for reliability, safety, and high accuracy, it delivers up to 1 kg per pack at speeds of 30-60 packs/minute. Perfect for exporters, manufacturers, suppliers, and traders in India.

Elevated Packing Solutions for Your Plant

The Automatic Dry Fruit Fill Sealing Machine offers advantageous high-speed operation, minimal waste, and outstanding accuracy. Its durable SS304 structure ensures long-term performance while advanced features like digital weigh filling and heat sealing enhance output. Widely used in dry fruit, nut, seed, confectionery, and snack production plants, it's equipped for continuous operation with safety redundancies, making it an optimum choice for all packaging facilities seeking efficiency and reliability.

Sample Services and Reliable Dispatch Process

Sample units of the Automatic Dry Fruit Fill Sealing Machine are readily available to potential clients. Our sample policy ensures each item is carefully handed over and inspected before packing and dispatch. The machines are securely packed for transportation via the specified FOB port, guaranteeing safe delivery and optimal condition. Clients can expect seamless sample acquisition, quick response times, and professional handling throughout every stage of the process.

Elevated Packing Solutions for Your Plant

The Automatic Dry Fruit Fill Sealing Machine offers advantageous high-speed operation, minimal waste, and outstanding accuracy. Its durable SS304 structure ensures long-term performance while advanced features like digital weigh filling and heat sealing enhance output. Widely used in dry fruit, nut, seed, confectionery, and snack production plants, it's equipped for continuous operation with safety redundancies, making it an optimum choice for all packaging facilities seeking efficiency and reliability.

Sample Services and Reliable Dispatch Process

Sample units of the Automatic Dry Fruit Fill Sealing Machine are readily available to potential clients. Our sample policy ensures each item is carefully handed over and inspected before packing and dispatch. The machines are securely packed for transportation via the specified FOB port, guaranteeing safe delivery and optimal condition. Clients can expect seamless sample acquisition, quick response times, and professional handling throughout every stage of the process.

FAQ's of Automatic Dry Fruit Fill Sealing Machine:

Q: How does the automatic dry fruit fill sealing machine ensure optimum packaging accuracy?

A: The machine utilizes a digital weigh filler controlled by Siemens PLC and HMI, ensuring precise measurement and uniformity for every pack. Heat sealing with temperature control further enhances accuracy and product integrity.Q: What types of packaging materials does the machine support?

A: The unit accommodates PP, laminate, PE, and other food-grade films, offering flexibility to meet various market and product requirements.Q: Where can the machine be installed for best use?

A: It's ideal for installation in food processing plants, confectionery facilities, dry fruit packaging centers, and snack production lines across India.Q: What is the sample policy for the dry fruit fill sealing machine?

A: Samples are made available to clients based on requirement, and each sample is meticulously handled, packed, and dispatched from the designated FOB port to ensure safe transportation.Q: How does the process of sample acquisition work?

A: Interested parties can request samples, which are carefully handed over after inspection, packed securely, and dispatched using reliable transportation channels for timely delivery.Q: What safety features are incorporated in the machine?

A: Key safety features include emergency stop, overload protection, and safety interlocks, guaranteeing safe and secure operation during production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Conveyors' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free